fulfillment &

fulfillment &supplied managed inventory

Pre-production die cut options

Pre-production die cut options  Post-Production die cut options

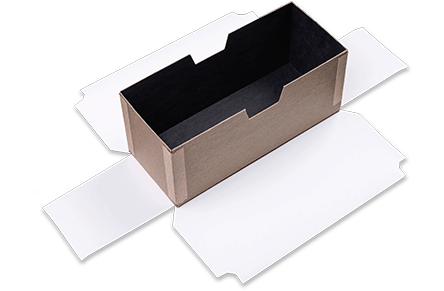

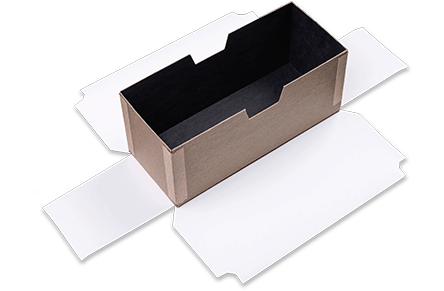

Post-Production die cut options  Wrapped Wide-V Notches

Wrapped Wide-V Notches  Lining Interior boxes

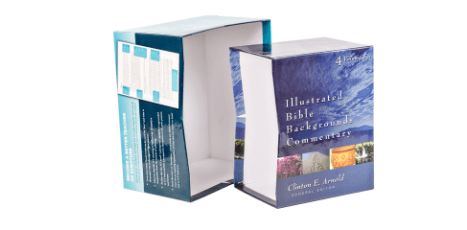

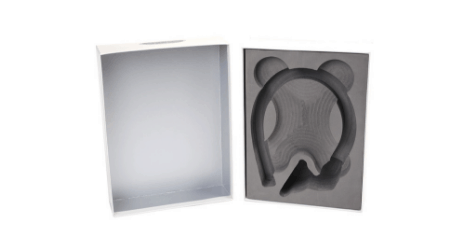

Lining Interior boxes  Custom inserts or sleeves

Custom inserts or sleeves

Board die cut to 1 up flat size. Exterior Paper (i.e. box wrap) is die cut to 1 up wrap size.

Die cut board blank pre-formed by machine. The machine applies glue to the entire back side of die cut paper; pre-formed chipboard box then precision machine spotted onto glued, die cut wrap.

Spotted box gets fed into the wrapper. Machine fully tight wraps exterior paper to the chipboard box. The machine then outputs a finished box, ready to be packed into a corrugated case.

Ready to get started?Request a Quote!